AMTS Monitoring System (Automated Motorized Total Station)

The AMTS (Automated Motorized Total Station) monitoring systems are deployed on construction and infrastructure projects to provide wide-area monitoring of surrounding structures. A handful of stations can cover hundreds of monitoring points in and around a construction site.

Each monitoring point consists of a prism whose position is tracked in three dimensions by an automated total station, registering displacements from hundreds of meters away.

WHY USE AMTS?

They have several key features that provide large-scale cost-effective monitoring.

- Automated: Automation provides 24/7 monitoring and rapid processing of measurements, allowing early identification of any unwanted displacements.

- Accurate: Multiple observations from a location and processing deliver accuracy similar to first-order manual surveys.

- Cost-effective: AMTS systems provide wide area coverage at a low cost per monitored point. Unattended operation and automated processing also lower costs and save time.

- Compatible: GKM Consultants’ software can output data as specified by the customer, suitable to combine with other geotechnical instrumentation or for use with CAD-generated plan views and as-builts.

HOW DOES IT WORK?

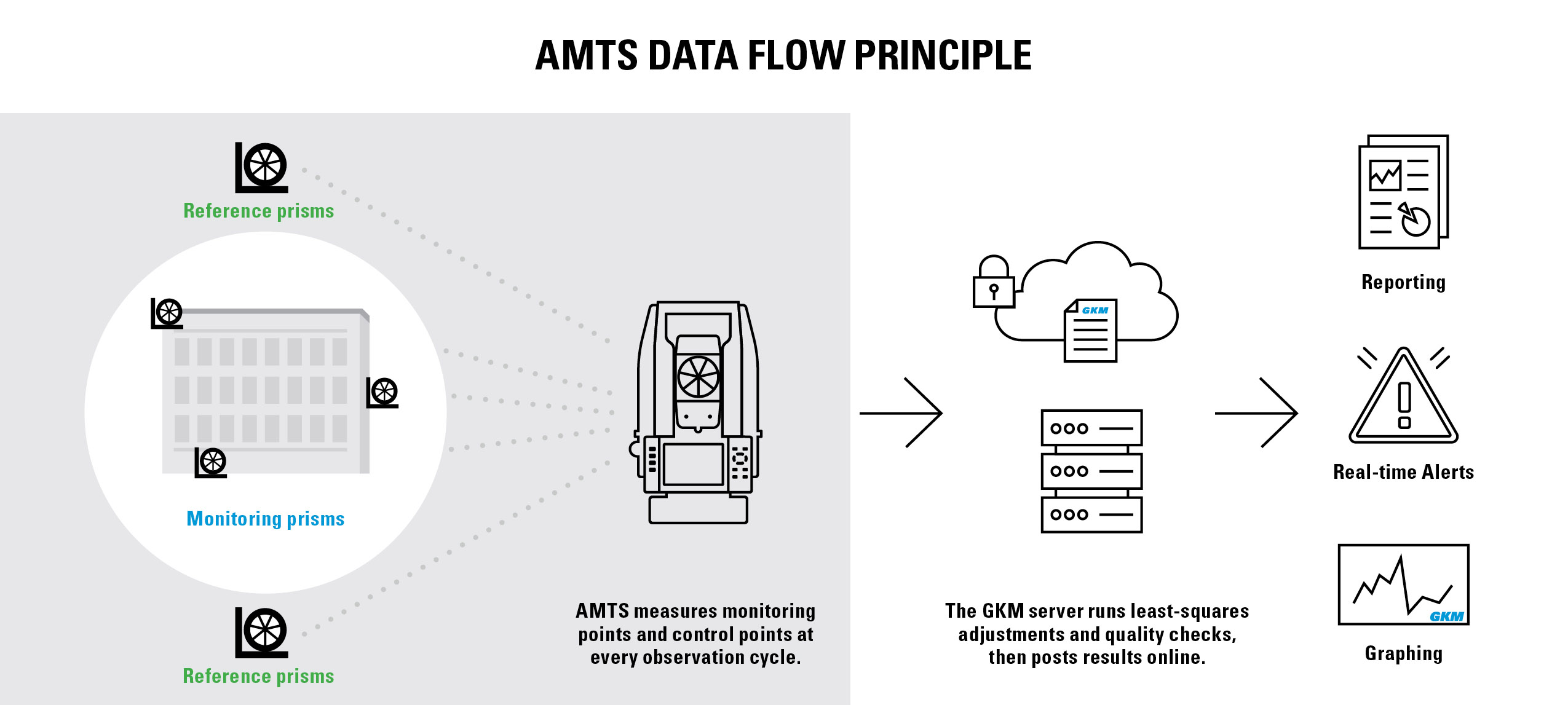

Optical monitoring involves prisms, measurements with a total station, and processing. Prisms are attached or affixed to critical points on a structure or on the ground, and the total station is used to record angles and distances to each prism. Reference targets installed outside the zone of influence allow the station to be installed in the middle of active areas and recalculate its position. The measurements are offloaded to software that applies statistically weighted adjustments and outputs coordinates for each prism.

Successive measurements on both monitoring and reference prisms are obtained at regular intervals and processed the same way. Changes in coordinates indicate that movement has occurred. The magnitude and direction of the movement are found by comparing current and initial coordinates. Data processing software automates these steps and delivers alerts, plots, and reports via a project website.

GKM Consultants deploys specialized prisms for different types of structures.

A wide variety of setups for the AMTS stand is also available and highly customizable with the project constraints. AMTS can be powered with solar panels and are controlled remotely in areas where cell coverage is available.

EXAMPLE APPLICATIONS

Tunneling projects

Tunneling projects under already-built areas can induce differential settlement that may affect buildings and structures outside the tunnel’s immediate vicinity as well as a settlement along any surface, including roadways, immediately above the new tunnel. AMTS offers the possibility of monitoring a large number of points in real-time located on surrounding buildings and the road surface. Underground, AMTS can be used efficiently to monitor convergence.

Structural health monitoring

Large structures such as bridges, dams, or skyscrapers are designed to be stable over time. However, changing conditions such as the addition of new infrastructure in the vicinity can affect the surrounding soil impacting the health of these structures. Short- and long-term monitoring of these structures can be conducted by locating prisms at regular intervals and tracking them over time.

Rail tracks, highways, pipelines

Linear structures such as rail tracks, highways, and pipelines are often vital to remain functional regardless of the works around them. AMTS with prisms or even reflectorless systems are able to detect very early disorders and send alarms to contractors and stakeholders.

Rock faces, slope, and retaining structures monitoring

Automatic monitoring of unstable slopes is an obvious necessity for safety reasons. Once prisms are in place, AMTS monitoring provides an efficient early warning system, working 24/7, in environments such as open pit mines, wall cuts for rail tracks, or any large retaining structures or abutments.

Large excavations

The walls of large excavations must be stable for the duration of any project to protect the workers, the project, and surrounding structures. An AMTS can monitor prisms located on the walls to track any deformation over time, providing critical information to engineers and managers. Surrounding buildings can be monitored concurrently with the same system.

Technical features

Monitoring points are installed at locations affected by construction activity. Reference points are installed at stable locations outside the zone of influence. AMTS measures both monitoring and reference points at every observation cycle and then transmits data to GKM Consultants’ servers on the internet. GKM Consultants’ servers run quality checks, then forward the processed data to the project database for alarm checks, data visualization, and storage.

Options

HD Road Prism

Road prisms are installed on road surfaces to monitor for settlement or heave.

Wall Brackets

Wall brackets can be installed on any wall or column.

Solar Power

Solar power is available for AMTS systems, eliminating the need for AC wiring.

L-Bar Prism

Versatile L-Bar prisms are the standard for most applications.

L-Bar Mini-Prism

L-bar Mini-Prisms are not as visible, making them less intrusive and more discreet.

Rail Clip Prism

Rail clip prisms are used for monitoring settlement and lateral displacement or tracks.

Towers

Gravity-base towers provide a stable location for AMTS when walls, columns, and rooftops are not available. Towers are semi-portable and can be relocated as necessary. They can also be custom-built according to the specific requirements of any location, including weight limits, height, and looks.

Parapet Brackets

Parapet brackets are secured by clamps, minimizing impact at the mounting location.